Production data acquisition

Bidirektional ProductionDataAcquisition: Bi-PDA

Bidirektional ProductionDataAcquisition: Bi-PDA

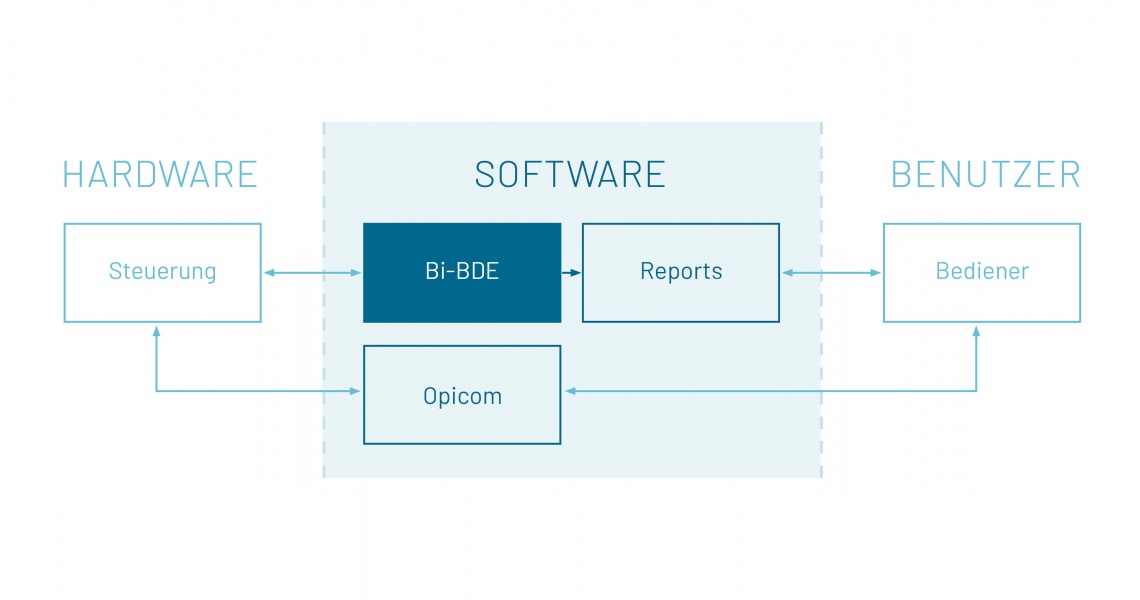

The production data acquisition system is a highly adaptable scripting environment that allows us to record current plant data and enables the communication between external data sources and the control system.

Data is recorded using an SQL database and can be exported periodically as CSV or XML files.

The BiPDA system works closely with both OPICOM and the reporting system to provide the operator with the necessary data and information, exactly where it is needed.

Data is recorded using an SQL database and can be exported periodically as CSV or XML files.

The BiPDA system works closely with both OPICOM and the reporting system to provide the operator with the necessary data and information, exactly where it is needed.