ESA ELEKTRO AUTOMATION GMBH Based in Viehdorf

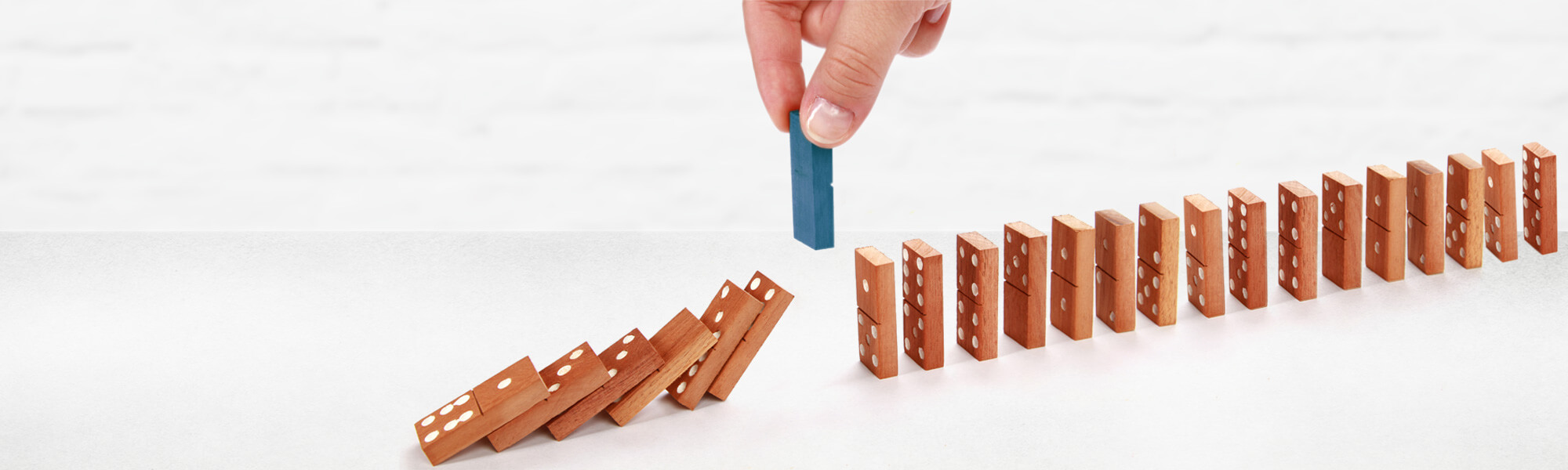

Concept development FOR PIONEERS

Be different. Be the first. Be both.

No two projects and no two plants are the same.

ESA, Tailoring solutions to your needs.

Tailor-made for MASTERMINDS

Strategic plans for masterminds

Every idea is worth thinking through.

Our extensive experience will bring your inspirational ideas to life.

Bringing the ensemble together WITH ORCHESTRATORS

A digital ensemble for orchestrators

Each component in a plant works flawlessly by itself.

However, individual components only reach their full potential when they work in harmony.

Whether you are looking for a comprehensive project – comprising production planning, optimisation and plant control – or a partial solution, you benefit from our many years of experience implementing successful projects on an international scale.

send an enquiry

send an enquiry

A sector-oriented focus

A sector-oriented focus

Developing solutions

Developing solutions

Controlling plants

Controlling plants

Automating companies

Automating companies

Sector-oriented consulting

Sector-oriented consulting  Change-Management

Change-Management

Data collection

Data collection

Interfaces & applications

Interfaces & applications

Software & systems

Software & systems

OPICOM – a manufacturing execution system

OPICOM – a manufacturing execution system